Introduction

You lace up, press Start, and… nothing. No beep, no belt, just a stubborn console and the feeling your whole plan for the day is slipping. We get it. A treadmill that won’t start is extra frustrating because it seems like it should be simple—one button and go. The truth is, a lot has to happen in that first second: the console needs clean power, the safety key has to be recognized, interlocks have to say it’s safe, the incline system has to know where “zero” is, and the motor control board has to deliver a clean surge of current to get the belt moving. If any one of those steps hiccups, you’re stuck staring at the screen.

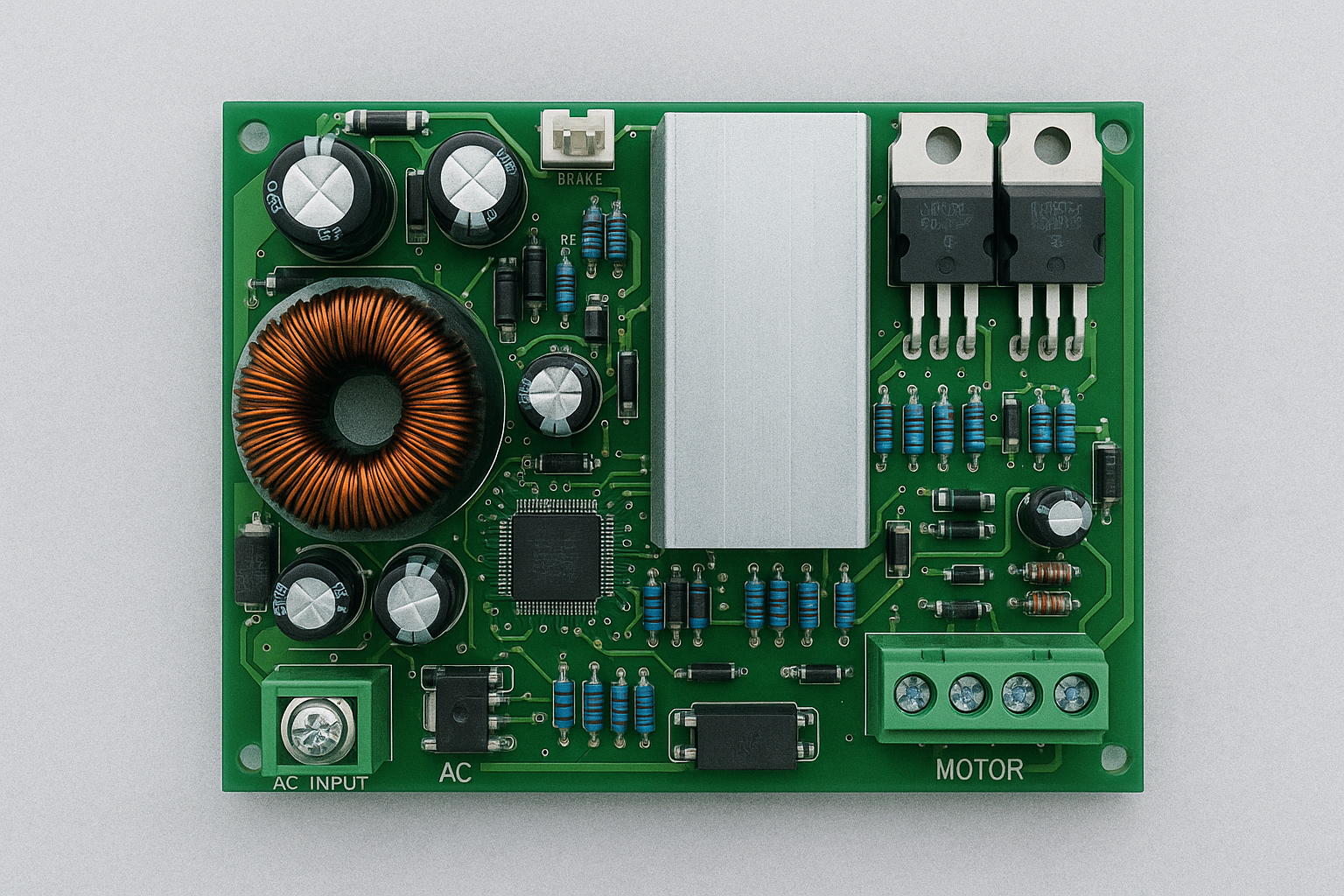

The good news is that many “won’t start” problems are easy wins: reseating the safety key, resetting a GFCI outlet, lowering a folded deck all the way, or correcting a speed-sensor gap can bring a machine back to life. When it isn’t one of those quick fixes, it’s often an electronic issue—most commonly the motor control board (MCB) or the console’s low-voltage power section. Those parts live a hard life of heat, vibration, dust, and occasional moisture, and over time their relays, capacitors, and solder joints get tired.

That’s where UpFix comes in. We don’t push replacements; we repair the board you already own so your treadmill keeps its exact, familiar behavior. On our bench, we simulate your start sequence, find the real failure (not just the symptom), and make a component-level repair—replacing heat-stressed power devices, refreshing weak capacitors, and reworking cracked solder at heavy components and headers. Then we stress-test through start, ramp, steady run, and coast-down to be sure it behaves under load, not just at idle. You get your original board back plug-and-play, with the model-correct feel you’re used to. And because life is busy, we back fitness board repairs with a strong warranty, keep you updated with repair tracking, and make shipping simple with a printable label and clear instructions—so the most complicated part of this process is taping up the box.

If you’re not sure whether to send the console or the motor board, tell us exactly what happens when you press Start—does the screen light, do you hear a relay click, does the belt twitch, do any codes flash? We’ll point you to the right module, help you avoid guesswork, and get you back to running without buying a whole new machine

Quick wins before you grab tools

Start where the easy answers live. Make sure the safety key is fully seated—many treadmills won’t do anything without it. Flip the main switch on the frame and test the outlet with a lamp you know works. If you’re on a GFCI outlet (garages/basements often are), press RESET. Avoid extension cords and thin surge strips; plug directly into the wall so the machine gets a clean surge of power at startup. If your treadmill has a little reset breaker or fuse near the cord entry, check it once; if it trips again, stop and look for the root cause instead of power‑cycling it to death.

If the console is dead, you may have a simple input power issue or a console low‑voltage problem. If the console lightsbut the belt won’t move, think safety key, fold/deck interlock, incline not finding zero, speed sensor spacing, belt/deck friction, worn motor brushes (on DC drive motors), or a motor control board that’s failing under load.

Why treadmills refuse to start

A lot has to go right in that first second: the console needs stable low voltage, interlocks must all say “safe,” the incline system often needs to know where “zero” is, and the motor control board (MCB) has to deliver a clean surge of power without tripping itself or your breaker. If any part of that chain hiccups—weak capacitors in the console, a mis‑read safety key, a dragging belt, worn brushes, or an MCB with heat‑stressed power devices—the start sequence collapses and you’re stuck staring at the screen.

What we do at UpFix (and why it works)

We fix the board you already own—no guessing with used parts, no reprogramming a replacement, no supply‑chain roulette. Our process is simple and built for reliability:

Bench diagnostics. We power your board on the bench and simulate the actual start/run sequence to see exactly where it drops out—separating console issues from MCB issues fast.

Component‑level repair. We replace failed relays, MOSFETs/IGBTs, regulators, refresh weak capacitors, rework cracked solder at heavy components and headers, and rebuild/guard any stressed traces.

Stress testing. After the repair, we run start, ramp, steady‑state, and coast‑down under load and watch the rails and feedback. If it won’t behave perfectly on our bench, it won’t leave our bench.

Plug‑and‑play return. Because it’s your original board, you reinstall it and go. No coding, no surprises—and on fitness boards, repairs include a 2‑year warranty and real‑time repair tracking so you can follow progress from your account. Many treadmill control board services also note free return shipping within the U.S. (exclusions apply).

Supported brands & board families (what we see most)

UpFix lists repairs across a broad range of treadmill brands and board families—NordicTrack, ProForm, Horizon, Sole, Life Fitness, Precor, Bowflex/Schwinn, Matrix, SportsArt, Star Trac, Technogym, Woodway, and many others, including common ICON board lines like MC2100/MC2100LT/MC2100LTS, MC1648, as well as Sole AE‑series and various OEM‑labeled motor controllers. As of today, many of these repair SKUs post at $159.99 (check your exact model page for current pricing)

A simple, troubleshooting flow

Start at the wall. Plug directly into a good outlet and reset any GFCI (Ground-Fault Circuit Interrupter) Seat the safety key firmly. Lower and latch the running deck if your frame folds. Power on and see if the console wakes. If it doesn’t, suspect the console’s power supply or an input fuse. If it wakes but won’t run the belt, try an incline calibration (many brands let you hold a key combo at power‑on), check speed‑sensor gap to the magnet, and loosen or properly lubricate a belt that’s too tight or dry. If you hear a click and the belt jerks or gives up, look hard at the motor control board and motor brushes next. Burning smell, visible scorching, or repeated tripped breakers? Stop. That’s electronics territory—and that’s when sending the board in is the smart move.

Case Study

The problem

A home treadmill (NordicTrack-style) looked alive: the screen lit up, programs loaded, and pressing Start made a soft click under the motor hood. But the belt didn’t move. Sometimes the console even restarted after the click. No burning smell, just a workout that never started.

What the owner tried

They did all the right first steps—reseated the safety key, plugged straight into a wall outlet (no power strip), reset the GFCI, lowered the deck fully, and checked belt tension. Same result: click, then nothing.

Describe Your Symptoms and we’ll point you in the right direction.

What we found

On our bench, we powered the treadmill’s motherboard (also called the motor control board). The board turned on and tried to start the motor, but the power dipped right at that moment. Two simple causes:

-

The big main capacitor on the board had aged. Think of it like a tiny battery that helps the motor get moving; this one couldn’t hold enough charge.

-

The motor wire connector on the board had a hairline crack in the solder. Under vibration, it made a flaky connection.

Together, those two things made the board “try,” click the relay, and then give up.

What we fixed

We replaced the tired main capacitor with a high-quality part, cleaned up and re-soldered the motor connector, and touched up a few other stressed joints so they won’t crack again soon.

How we tested it

We ran a full start-to-run test on our load stand—start, ramp up, steady speed, and stop—several times in a row. No dips, no resets, no surprises.

The result

Back at home, the customer pressed Start and the belt moved smoothly on the first try. We suggested a quick belt/deck service (correct lube and tension) so the electronics don’t have to work overtime.

What you can learn from this

If your treadmill clicks but the belt won’t move, the motherboard is a prime suspect. Aging power parts and tiny cracked solder joints are common and fixable. Keeping the belt properly lubricated and not over-tight helps the board last longer.

Ship it right

If your checks point to electronics, remove just the motor control board or the console board—whichever is most suspect. Protect connectors with soft wrap or an antistatic bag and pack the board so it can’t move in the box. Slip in a note with your name, phone, email, treadmill brand/model, and a short, clear symptom line: “console lights, relay clicks, belt won’t move,” “starts then shuts off after 5 seconds,” or “dead console, outlet tested good.” UpFix provides a shipping label at checkout, and repair pages commonly note free return shipping for U.S. orders (exclusions apply). Use the address on your order confirmation (the site lists Buford, GA; some pages specify Suite 100). If you’re local, lobby hours for drop‑off/pick‑up are posted.

Repair vs. replace

New boards are expensive, sometimes unavailable, and can behave differently from your original. Used boards are a gamble—you inherit someone else’s problem. Repair goes after the root cause—power devices, relays, capacitors, solder joints—so the fix is real, cost stays sane, and your treadmill runs the way you expect. And with a 2‑year warranty on fitness board repairs plus real‑time repair tracking, the peace of mind is built in.

FAQs

Console lights but the belt won’t move. Where do I look?

Start with the speed sensor gap and belt friction; then check motor brushes on DC motors; if you hear a relay click and it gives up, the motor control board is a strong suspect.

Dead console on a known‑good outlet—board or something else?

Likely the console’s low‑voltage power supply or an input fuse. If the console lights but resets under load, still suspect the console’s power section.

Do you support my brand?

UpFix’s treadmill category spans hundreds of models across NordicTrack, ProForm, Horizon, Sole, Life Fitness, Precor, Bowflex/Schwinn, Matrix, SportsArt, Star Trac, Technogym, Woodway, and more—plus common ICON families like MC2100 variants. Check your model/board family before you ship. To see for yourself Go to UpFix.com

How long does a repair take? What’s the warranty?

Representative product pages list 3–5 business day repair windows with 2‑year warranty, real‑time tracking, and free U.S. return shipping on many services.

Where do I ship?

Use the address on your order confirmation. The site lists the Buford, GA facility, with some pages specifying Suite 100; a shipping label at checkout is commonly provided. U.S. and Canada shipping options are available.

If you have any unanswered questions please contact us

Conclusion

A treadmill that won’t start can derail your whole routine, but the path to a fix is usually straightforward. Work the basics first: seat the safety key firmly, plug directly into a good outlet and reset any GFCI, lower and latch the deck, and try an incline calibration if your model supports it. If the console wakes but the belt won’t move—or starts, clicks, and gives up—you’re probably looking at a speed-feedback issue, belt/deck friction, tired motor brushes, or, most commonly, a motor control board that’s failing under load. That’s not a reason to give up on the machine; it’s a sign the electronics need attention from people who do this every day

At UpFix, we fix the problem at its source. We diagnose on the bench, replace the components that actually fail, and validate the repair under real load before your board leaves our shop. Because you’re keeping your original hardware, you avoid the cost and uncertainty of used parts, the delays and mismatches of replacements, and any reprogramming headaches. The result is a plug-and-play return that feels like your treadmill always did when it was healthy—press Start, the belt moves, and you get on with your run.

If you’re ready to move forward, jot down your symptoms —“console lights, relay clicks, belt won’t move,” “starts then shuts off after five seconds,” or “dead console, outlet tested good”—and pack up the suspect board with the connectors protected so nothing gets bent in transit. We’ll take it from there: bench diagnostics, component-level repair, stress testing, and a return shipment you can track. Your workout routine gets its rhythm back, and your treadmill gets a second life without the price tag of a new one.

When you’re set, use the options that fit where you are in the process: Start a Treadmill Board Repair if you’re confident it’s the electronics, Talk to a Technician if you want a quick sanity check, Describe Your Symptoms if you need help deciding which module to send, Request Pricing & Turnaround if you’re planning ahead, or Download Packing Checklist when you’re ready to box it up. The next time you press Start, the only thing that doesn’t start is the excuses.

upfix.com

upfix.com 888-979-9343

888-979-9343