How to Fix Servo Drive’s Erratic Motion?

Erratic servo motion is one of the most disruptive issues in automated systems. It leads to performance loss, excessive vibration, and system instability that can halt production or damage components. These problems often stem not from the motor itself but from underlying causes such as incorrect parameter settings, faulty encoder feedback, or internal electronic faults. Diagnosing the true source of the issue requires technical precision and specialized equipment. At UpFix, we specialize in identifying and resolving complex servo-drive issues with precision and reliability. For expert servo drive repair, please reach out to our team today.

Understanding Servo Drive Motion Control

Servo drive motion control is the foundation of precision automation systems. It involves complex interactions between electrical inputs, mechanical components, and control algorithms. Before analyzing specific issues, it helps to understand how servo drives translate commands into controlled motion. This understanding allows technicians to identify potential instability or feedback errors early. In the breakdown below, we explore how these systems maintain accurate positioning and torque regulation.

What a Servo Drive Does?

Servo drives are essential components in modern motion control systems, designed to control motor behavior in industrial applications precisely. They interpret control signals and adjust electrical output to achieve the desired speed, torque, and position. By maintaining tight coordination between the command input and the feedback response, they ensure smooth, accurate motion. Understanding how they function helps operators recognize why instability may occur. A servo drive manages motor speed, torque, and position by continuously processing sensor feedback. Its control system uses a PID loop (Proportional-Integral-Derivative) to ensure the motor follows the commanded motion accurately. The drive adjusts voltage and current in real-time to match the target position and velocity. When this control loop is disrupted by feedback noise or parameter errors, the system can experience jitter or oscillation. Even a single misinterpreted signal can cause sudden torque spikes or unpredictable movement. This is why tuning and calibration are vital to maintaining a stable servo loop. We use advanced diagnostic tools to verify feedback integrity and ensure stable, smooth performance.

Why Stability Matters in Precision Systems?

In precision-driven industries, even minor motion irregularities can compromise production accuracy and part quality. Vibration or inconsistent motion increases mechanical stress, leading to premature bearing wear and reduced machine lifespan. Servo feedback synchronization ensures multiple axes move in harmony. Unstable motion can also pose safety hazards during high-speed operations. Through precise calibration, we restore motion synchronization and eliminate these risks. UpFix’s calibration expertise ensures all control signals remain within OEM specifications, guaranteeing the accuracy and reliability your system demands.

Common Causes of Erratic Servo Drive Motion

Erratic servo performance can stem from several interconnected factors affecting both electrical and mechanical systems. Understanding these root causes helps prevent unnecessary component replacements and ensures accurate troubleshooting. Each cause requires targeted diagnostics to maintain system precision and longevity. By breaking down the major contributors to instability, technicians can more efficiently pinpoint and resolve motion irregularities. Below, we explain the key sources of servo drive inconsistency and their repair approaches.

Incorrect Parameter Settings

Improper gain, acceleration, or torque limits can cause servo overcorrection and vibration. In many cases, incorrect PID parameter tuning leads to hunting, where the motor continuously overshoots its target position. This issue often arises during system setup or after replacing components without reprogramming. As part of troubleshooting a servo motor problem, we assess your drive’s control parameters to detect mismatches or instability sources. Our technicians recalibrate gain and damping settings to factory standards. At UpFix, we restore servo drives using OEM specifications to ensure factory-level motion smoothness and performance.

Encoder or Feedback Issues

Servo drives depend on accurate encoder or resolver feedback to determine motor position and velocity. When encoders are damaged or feedback cables degrade, the drive receives inconsistent or noisy signals. This can lead to jittery motion, position drift, or total loss of synchronization. Misalignment or contamination in the feedback sensor can also introduce phase mismatches that disrupt control accuracy. Our experts test and replace damaged encoders, feedback circuits, and connectors. At UpFix, we ensure your drive maintains stable feedback integrity for precise motion response across all applications.

Electrical and Power Problems

Power quality issues often cause servo instability. Ripple voltage, grounding errors, or electrical noise can affect the drive's control logic. Damaged power transistors or voltage regulators can cause irregular drive outputs, leading to erratic motor behavior. Over time, component fatigue or poor grounding can worsen these symptoms. Our diagnostics include in-depth power integrity tests to isolate these faults. UpFix repairs these issues at the component level, replacing transistors and capacitors to restore clean, stable drive operation under all load conditions.

Mechanical System Faults

Mechanical irregularities often mimic electrical servo drive issues. Worn couplings, loose mounts, or damaged bearings can transfer vibrations back into the system, confusing the feedback loop. Misalignment between the motor shaft and load can introduce additional instability, even when the drive functions correctly. Our specialists identify whether instability stems from mechanical resonance or electrical feedback. Through combined mechanical and electronic diagnostics, UpFix determines the root cause and ensures long-term system reliability.

Advanced Troubleshooting for Erratic Servo Motion

Effective troubleshooting requires a structured, analytical approach. Before applying any repair, it’s important to confirm the source of the irregularities. A methodical step-by-step inspection prevents misdiagnosis and protects system integrity. By addressing electrical, feedback, and control parameters in sequence, we can restore smooth servo motion. The breakdown below outlines each critical diagnostic stage used to identify and correct drive instability.

Step 1 – Inspect Power and Ground Integrity

Before internal analysis, it’s vital to confirm the power supply and grounding are stable. Verify voltage levels, ground continuity, and ensure cable shields are properly terminated. Even small grounding issues can lead to system-wide instability. Consistent DC bus voltage under varying loads prevents unexpected surges or drops. Following this guide to servo maintenance, we test both the power input and return paths to confirm electrical balance. This step ensures stable power delivery before advancing to signal-level diagnostics.

Step 2 – Verify Encoder and Feedback Signals

Encoders and resolvers form the communication bridge between motor and drive. Using oscilloscopes, we analyze encoder waveforms to detect missing pulses, phase mismatches, or degraded signal amplitude. Weak or distorted signals can mislead the control loop, causing inaccurate torque output. Proper shielding and alignment are crucial for accurate position reporting. UpFix engineers test feedback quality under dynamic motion conditions to ensure clean, synchronized signals. We replace faulty feedback lines or connectors as part of our complete diagnostic service.

Step 3 – Evaluate Control Loop Parameters

Once feedback and power systems are verified, tuning the PID control loop becomes essential. Overly aggressive proportional gain or insufficient damping can cause oscillation and noise. We monitor system response to step inputs and fine-tune gain ratios for maximum stability. Adjusting these parameters ensures fast yet smooth response without overshoot. The evaluation also includes drift and delay analysis for long-term performance validation. Our calibration experts ensure your control loop maintains precise tracking accuracy under all loads.

Step 4 – Check Internal Drive Components

If external parameters test correctly, the problem likely lies inside the drive itself. Faulty transistors, aging capacitors, or damaged control ICs can alter output response. Overheating is another common failure point, especially in drives exposed to high-duty cycles. Internal inspection involves full board-level analysis using thermal imaging and electronic testing tools. When faults are detected, we perform bench-level component replacement using certified parts. Once repaired, drives undergo multi-phase load simulation before returning to service.

Case Study – Fixing Erratic Servo Motion in a CNC Application

A manufacturing client reported that one of their CNC axes intermittently vibrated and overshot target positions. The machine had already undergone motor and wiring replacements, yet the issue persisted. Upon inspection, UpFix engineers discovered a damaged encoder input circuit causing signal dropout. This defect led the drive to lose feedback data, triggering uncontrolled oscillations intermittently. Our team replaced the faulty input IC, recalibrated the PID parameters, and conducted dynamic load testing. After reinstallation, the axis achieved smooth, stable performance. The repair saved the customer more than 75% compared to OEM replacement costs and prevented costly production downtime.

How UpFix Repairs and Stabilizes Servo Drives?

Repairing servo drives requires technical depth and specialized calibration methods. Every step we perform—from diagnostics to final verification—ensures lasting performance stability. Understanding our workflow helps clients see how we restore functionality at the component and signal level. Our process is built to eliminate recurring failures and achieve long-term precision. Here’s an overview of how UpFix brings damaged servo drives back to optimal operation.

Comprehensive Diagnostic Testing

We begin by analyzing feedback loops, signal paths, and power circuits to detect irregularities. Our real-time testing replicates operational load conditions, using simulated encoder signals to monitor system response. By recreating the exact environment where faults occur, we can identify hidden or intermittent failures. These diagnostics reveal whether the issue lies in feedback processing, control logic, or power regulation. At UpFix, our advanced diagnostic procedures deliver accuracy and minimize guesswork, allowing us to provide consistent, high-quality repair outcomes.

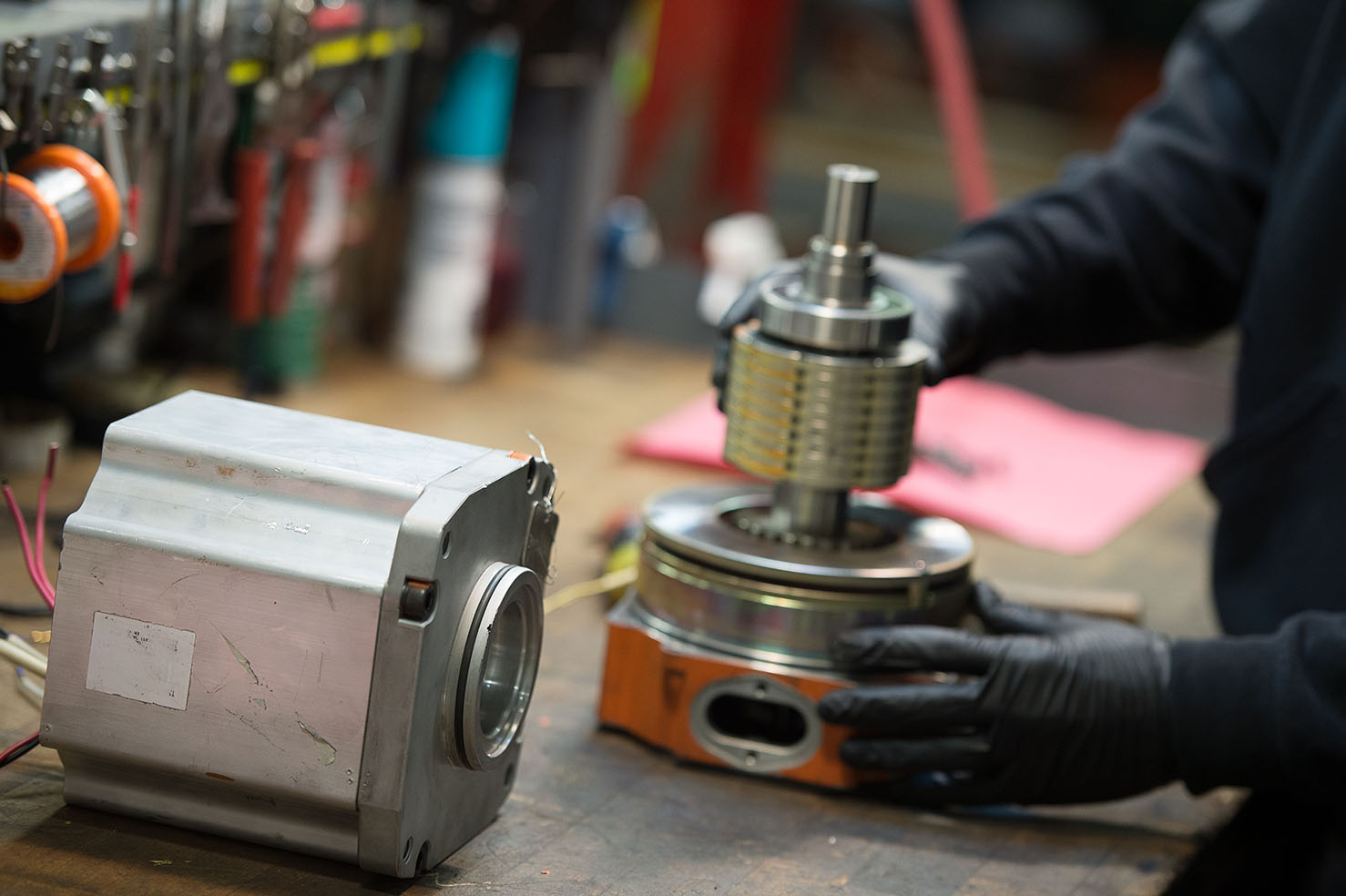

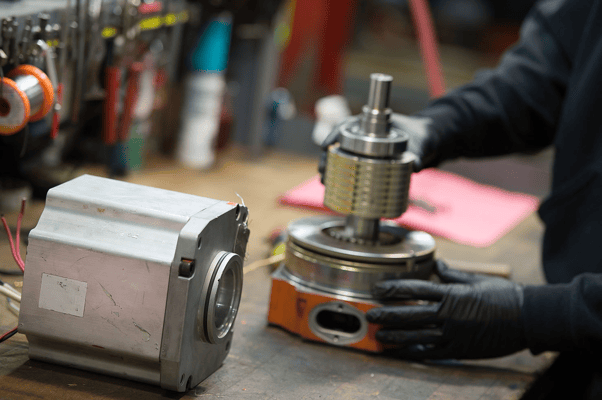

Component-Level Repair Process

After diagnostics, we perform component-level repairs on all defective circuits. Our IPC-certified technicians replace damaged integrated circuits (ICs), capacitors, transistors, and regulators. We also restore solder joints and repair broken PCB traces that cause signal interruptions. Each board undergoes ultrasonic cleaning and receives protective coatings to resist vibration and moisture exposure. Every repair follows strict ESD-safe and OEM-aligned standards to ensure durability. Through this detailed process, we restore drives to their original performance specifications or better.

Calibration and Verification

Once repaired, each servo drive enters our calibration and testing phase. We fine-tune PID and gain parameters to achieve smooth acceleration and deceleration profiles. Drives are tested under variable loads and temperature cycles to simulate real operating conditions. Our process guarantees that repaired units remain stable under production-level demands. After testing, drives are shipped plug-and-play, requiring no reprogramming or customer setup. This ensures immediate reintegration into your production line with minimal downtime.

Supported Brands and Applications

Servo drives are used in a wide range of industries, and compatibility is key to successful repair. Our extensive brand coverage ensures clients can rely on UpFix for nearly any platform or configuration. Each manufacturer requires unique diagnostic and calibration tools tailored to its system architecture. This variety highlights our adaptability across industrial automation fields. Below are some of the leading brands and applications we support every day.

UpFix supports a wide range of servo brands, including Yaskawa, Siemens, Mitsubishi, Allen-Bradley, Fanuc, ABB, Bosch Rexroth, Delta, and Panasonic. Our expertise extends to both industrial and automotive servo systems, ensuring flexibility across diverse environments. Whether repairing legacy servo drives or next-generation digital units, our technicians are equipped with brand-specific tools and schematics. This enables accurate calibration and reliable performance across all supported applications.

Why Choose UpFix for Servo Drive Repair?

Choosing a qualified repair provider can determine the success and reliability of your servo systems. Our long-standing record demonstrates how expertise and precision directly benefit customers. We approach every repair with attention to detail, industry knowledge, and commitment to fast turnaround. Beyond technical capability, we deliver measurable savings and reduced downtime. Here’s why companies across industries continue to trust UpFix for their servo drive repair needs.

Proven Technical Expertise

UpFix has successfully completed over one million control system repairs since 2006. Our IPC-certified engineers specialize in restoring high-precision motion control systems across industries. Each repair aligns with our EEAT-based quality standards, emphasizing expertise, experience, authority, and trustworthiness. We apply the same high standards across all brands and configurations. Our goal is to ensure every servo drive leaves our facility fully restored and validated for operational precision.

Cost and Time Benefits

Repairing with UpFix can save customers 50–80% compared to the cost of a full replacement. Our typical turnaround time is just 2–5 business days, including diagnostics and performance testing. All repairs include documentation detailing fault sources, replaced components, and calibration data. Most importantly, repaired units retain their original firmware and configuration, eliminating the need for reprogramming. Customers consistently report reduced downtime and higher production reliability after working with UpFix. For fast, affordable, and precise servo drive repair, contact our team today or watch the video below.

Customer Reviews and Testimonials

Client feedback provides valuable insight into our service quality and consistency. Reviews highlight how effective repairs improve operational efficiency and reduce maintenance costs. Our reputation is built on transparent diagnostics and dependable support throughout each project. Many of our customers emphasize improved motion control and performance reliability. The following testimonials reflect our dedication to excellence in every servo drive repair.

10/4/2025

-jpg.jpeg?width=400&height=374&name=1c6dff7790561246d0f1e5baf6008a4b%20(1)-jpg.jpeg)

They have made every effort to meet or exceed my expectation. Their follow up was surprisingly superior to my expectation.

-Donald

9/2/2025

-jpg.jpeg?width=400&height=374&name=1c6dff7790561246d0f1e5baf6008a4b%20(1)-jpg.jpeg)

Everything was good on service

-Mauricio M.

8/6/2025

-jpg.jpeg?width=400&height=635&name=d3a00a94ed61f9aa72f20f9911f3de96%20(1)-jpg.jpeg)

Excellent, I will use this service again. Thanks

-Vicente

FAQs – Servo Drive Power Issues

Understanding common power concerns helps operators maintain reliable motion systems. These FAQs clarify how electrical inconsistencies influence drive stability and performance. The questions below are based on real-world client cases we’ve solved successfully. Each answer aims to educate users about both prevention and proper repair methods. Explore the following insights to manage your servo drive’s electrical health better. Power-related faults are among the most common yet misunderstood problems in servo drives. Understanding these issues can help prevent costly breakdowns and downtime.

Q1: What causes erratic motion in a servo drive?

Erratic motion often results from degraded feedback signals, incorrect parameter tuning, or internal drive faults. Electrical noise and unstable voltage can also contribute to inconsistent motor response.

Q2: How do I know if the issue is electrical or mechanical?

If vibration persists even with correct parameter settings, mechanical causes such as worn couplings or misalignment may be at fault. UpFix diagnostics identify the exact fault origin using both electrical and mechanical analysis.

Q3: Can UpFix repair drives from any manufacturer?

Yes, UpFix services a broad range of brands, including Siemens, Yaskawa, Mitsubishi, and Fanuc. Our cross-brand expertise allows us to handle both analog and digital servo platforms.

Q4: How long does calibration and testing take?

Most repairs are completed within 2–5 business days, depending on component availability and testing requirements. Each unit undergoes dynamic testing under simulated operating loads.

Q5: Will the repaired unit require reprogramming or tuning?

No, UpFix delivers plug-and-play-ready drives. We ensure all firmware and settings remain intact for seamless reinstallation.

Expert Maintenance Tips to Prevent Future Motion Errors

Proactive maintenance extends the life and efficiency of servo drives. Small routine actions can prevent costly failures and production interruptions. Keeping track of cable conditions, temperature, and cleanliness ensures stable operation. By integrating these preventive measures into your schedule, you can significantly improve reliability. Below are expert recommendations designed to help you maintain optimal drive performance.

Preventive maintenance helps extend the lifespan and reliability of servo drives. Regular checks and proper environment management are essential for stable performance.

- Inspect encoder connections and shielded cables regularly to prevent signal loss.

- Maintain clean, dry environments to reduce moisture-induced circuit corrosion.

- Monitor temperature and vibration levels to detect early signs of component fatigue.

- Schedule annual calibration checks for systems requiring high-precision control.

- Use surge protectors or power conditioners to guard against electrical interference and transients.

Restore Smooth Motion with UpFix

Understanding the root causes of servo instability is essential to maintaining industrial precision and productivity. With advanced diagnostics, component-level repair, and calibrated restoration, UpFix delivers lasting solutions to erratic motion issues. Our repair services combine technical expertise and unmatched cost-efficiency with replacements. Trust our proven track record and attention to detail for every servo repair.

Erratic servo drive motion doesn’t mean the end of your system’s service life. At UpFix, we provide expert-level diagnostics and repair solutions for your servo drive, restoring performance faster and at a lower cost than OEM replacements. We invite you to start a repair order or call 888-979-9343 for a technical consultation. Our team guarantees quick turnaround, precise calibration, and long-term reliability. Experience our commitment to precision through the UpFix promise: Smart Repairs. No Guesswork. Join the UpFix forum for expert insights, maintenance advice, and repair success stories.

upfix.com

upfix.com 888-979-9343

888-979-9343