How UpFix Keeps school buses transmissions in check.

Last updated:

Introduction

When a Blue Bird school bus flashes “Shift Inhibited,” slips into limp mode, or refuses to move out of neutral, it’s more than a mechanical hiccup. It’s a missed pickup, a rerouted morning, and a lot of worried people asking what went wrong. In our experience, the culprit is often the Allison Transmission Control Module—the TCM that tells the transmission when and how to shift. When it misbehaves, everything around it gets harder: schedules, staffing, traffic, and, most importantly, safety.

At UpFix, we focus on repairing the TCM you already own and trust. We work at the component level, fix what actually failed, and send your original module back plug-and-play. You don’t have to hunt for a replacement, worry about backorders, or deal with reprogramming. Your calibration stays intact. Your team reinstalls the unit, turns the key, and gets the bus moving again. That quick return to service isn’t just convenient—it helps keep school districts safe, your kids safe, and the roads safe during the busiest hours of the day.

We set our process up for real-world fleet life. Transportation departments need predictable timelines, clear communication, and simple paperwork. We support purchase orders, tax-exempt processing, and bulk RMAs. We match asset tags, label everything clearly, and keep you posted while the unit is on our bench. The goal is to reduce downtime and eliminate surprises so the first bell rings on time and the curb stays calm.

If you’re dealing with a bus that won’t shift, shuts down once it warms up, or keeps throwing the same transmission codes, we can help you sort out what’s going on. Share what you’re seeing—any messages on the dash, any patterns you’ve noticed—and we’ll guide you through the next step. If it points to the TCM, we’ll get your repair started, give you a practical timeline, and make shipping painless with a straightforward packing guide. And if you’re weighing repair versus replacement, we’ll lay out the cost and turnaround so you can make a confident call for your district.

When everything works, you don’t notice the TCM at all. Buses leave the yard, kids get to class, and the flow around schools stays steady. That’s the standard we want you to get back to—reliable, routine, and safe

Common TCM Symptoms in Blue Bird Fleets

-

“Shift Inhibited” message, no movement or stuck in one gear

-

Limp mode (limited gear range, reduced power)

-

Harsh or delayed shifts, flare or bang into gear

-

Intermittent no-start because the TCM won’t authorize neutral/park logic

-

Communication loss (no data to scan tool, intermittent CAN comms)

-

Repeated transmission codes that return after clearing (solenoid driver, pressure control, speed sensor logic)

-

Random resets or TCM hot smell / visible board discoloration (less common but serious)

Not sure it’s the TCM? Tell us what the driver sees and we’ll help you confirm.

Our Process (What Happens at UpFix)

1) Intake & Bench Diagnostics

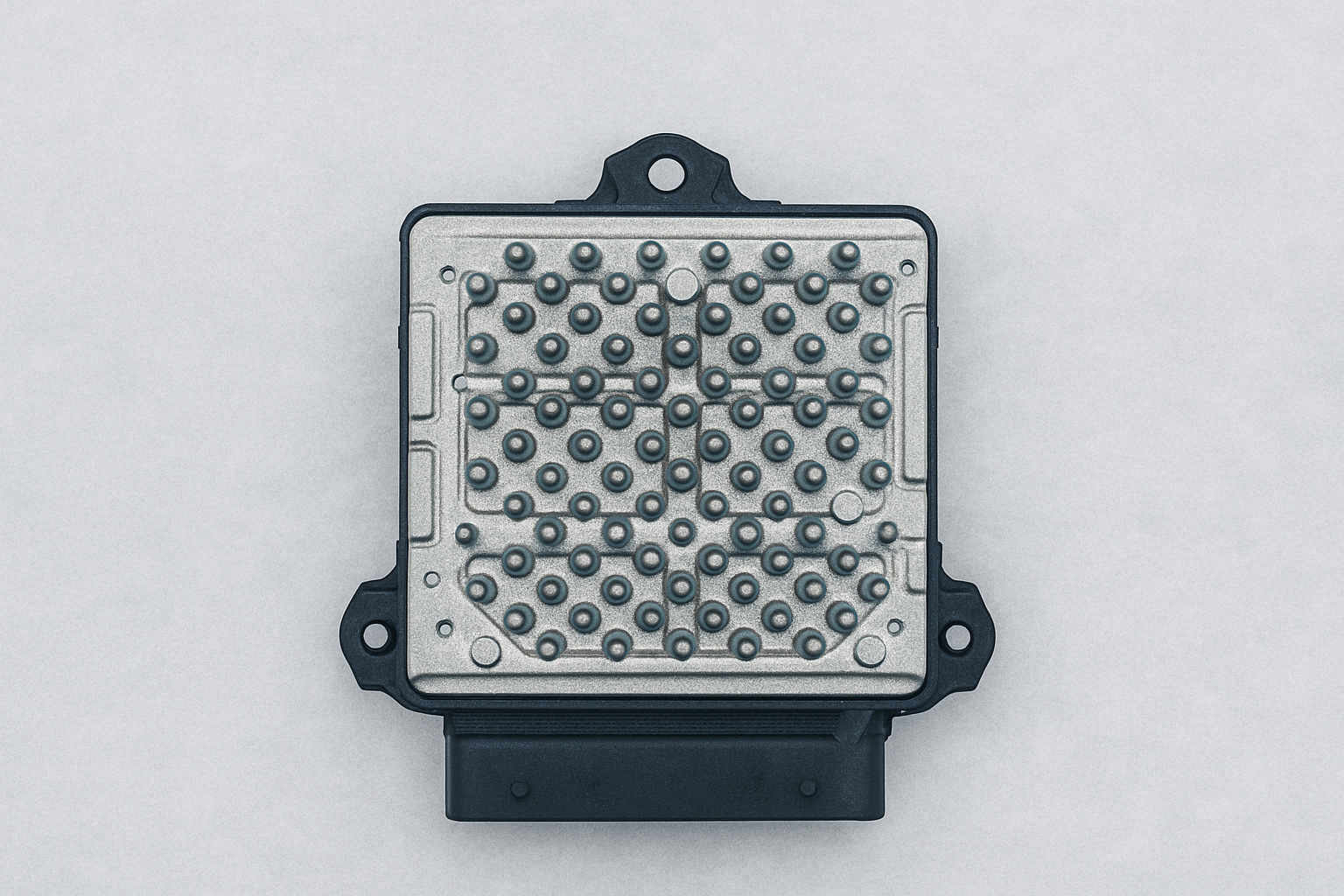

We power and communicate with the TCM, verify comms health, read/record fault behavior, and simulate key inputs/outputs.

2) Root-Cause Analysis

Board-level inspection for overheated drivers, failing capacitors, micro-cracked solder, contamination, and trace damage.

3) Precision Repairs

-

Replace failed driver components and stressed caps/regulators

-

Rework solder on high-load pins and connectors

-

Rebuild compromised traces; clean and treat corrosion

-

Seal where appropriate to mitigate future moisture

4) Functional Validation

We re-test communication stability, solenoid command behavior, power-on sequencing, and thermal stability on the bench.

5) Final QC & Return

Your original Allison TCM returns ready to install, retaining your calibration. No dealer reprogramming, no “universal” guesswork

Case Study 1

Case 1 — Blue Bird Vision, Allison 2000/3000

-

Before: “Shift Inhibited,” intermittent comms; codes returned after clears.

-

Findings: Heat-stressed driver IC and cracked solder at header pins.

-

Repair: Driver replacement + solder reflow, power section refresh.

-

Result: Normal comms, no “Shift Inhibited,” smooth engagement after install.

How to Send Your Module to UpFix

1) Start the repair order online.

Go to UpFix, pick the service (e.g., Transmission/TCM, Instrument Cluster), and create your repair order. For oddball models, use the Custom Repair Request form. In some categories, UpFix provides a shipping label at checkout; otherwise you’ll ship with your preferred carrier.

2) Remove the part and pack it safely.

UpFix’s shipping instructions are simple: carefully remove the unit, place it in a sturdy box with padding that prevents movement, and protect connectors (antistatic bag or soft wrap helps). Include a sheet inside the box with your name, return address, phone, and email; adding vehicle/bus details (year/make/model) helps the bench team.

3) What not to include in the box.

If you have special requests or want to update instructions, don’t leave long notes in the box—send those by phone or email after the part arrives so they’re attached to your order in the system. Keep your tracking number handy. info.upfix.com

4) Ship to UpFix’s current address (or drop off).

Use the address on your order confirmation. As listed on UpFix’s site today, the repair center address is:

UpFix, 4991 B U Bowman Dr, Buford, GA 30518.

Walk-in drop-off/pick-up is available Mon–Fri, 9:00 AM–5:00 PM ET; support by phone is Mon–Fri, 8:00 AM–6:00 PM ET.

When It Isn’t the TCM

Sometimes the module is innocent. A genuine mechanical problem in the transmission, an out-of-range speed or range sensor verified by direct testing, a broken shifter linkage, or a major open or short in the harness will all produce symptoms that rhyme with a bad TCM. When you send us a module with a short description of what the driver sees and what the scan tool says, we’ll help confirm whether the electronics are really to blame.

Why Repair Beats Replacement for Districts

Repair keeps the part that already knows your bus. Your calibration stays where it belongs, and your driver doesn’t spend a morning learning how a “new” module behaves. Repair also avoids the supply-chain circus and the line on your budget that nobody wants to write. Most importantly, it fixes the real cause—driver stages that no longer drive properly, voltage rails that can’t hold up, solder that only conducts when it’s in a good mood—so the fault doesn’t quietly return.

Instrument Cluster Problems in Blue Bird Buses (We Fix These Too)

While the Allison TCM gets most of the attention, a lot of Blue Bird fleets tell us they’re fighting instrument clustertrouble as well. It shows up in ways that make a long day feel longer: gauges that freeze or drift, backlights that flicker or go dark, odometers or LCDs that lose pixels, warning lamps that light up when nothing’s wrong—or refuse to light when something is. Drivers end up guessing at speed, fuel, or engine status, and dispatch gets a steady stream of “is this bus okay to run?” calls.

Most of these headaches come from the cluster’s electronics, not the sensors out on the vehicle. Heat, vibration, and time take a toll on stepper motors, surface-mount LEDs, voltage regulation, and tiny solder joints. A motor that sticks will leave a needle parked in the wrong place. A weak power section can make the whole panel reboot or dim at random. Cracked solder around the connectors can create those maddening, intermittent dropouts that only appear on rough roads.

We handle clusters the same way we handle TCMs: repair the original unit at the board level and send it back plug-and-play. We test the cluster on the bench, open it carefully so lenses and tabs survive, and go straight to the root cause—replacing failed stepper motors, restoring backlighting, reworking suspect solder, and stabilizing power rails. Before it leaves, we run sweeps and light tests so needles return to true zero, indicators illuminate cleanly, and the display looks the way it should look in the cab.

Getting clusters right isn’t just about convenience. Clear gauges and stable indicators reduce roadside surprises, help drivers make better decisions in traffic, and keep the school day running on time. If you’re already sending in a TCM and a bus has cluster symptoms, tell us in your note. We can set up a separate RMA for the cluster, or coordinate timing so both pieces come back ready to reinstall, with the same straightforward paperwork and one-year warranty you get on our transmission electronics.

Case 2 — Blue Bird All American, Route Bus

-

Before: Limp mode after warm-up, harsh 2-3 shift, resets over bumps.

-

Findings: Failing capacitors in power regulation and micro-cracks on the board near mounting points.

-

Repair: Capacitor pack replacement, trace reinforcement, vibration-stress rework.

-

Result: Full shift range restored; no post-repair codes in 30-day follow-up.

FAQs

Will we need to program the TCM after repair?

No. We repair your original unit; it returns plug-and-play with your calibration intact.

Can a weak battery or bad ground mimic a bad TCM?

Absolutely. Always validate power/ground before condemning the TCM.

Do you support bulk repairs or multiple simultaneous RMAs?

Yes—batch processing is common for districts. We provide RMA labeling and status updates.

What’s the warranty?

Repairs come with a one-year warranty and full functional bench testing.

Turnaround time?

Most TCMs are diagnosed, repaired, and shipped back within a few business days from receipt.

Conclusion

A bad TCM can turn a normal route into a scramble. The bus hesitates, drops into limp mode, or refuses to shift at the worst possible time, and suddenly drivers, dispatchers, parents, and administrators are all working the problem at once. The fastest way out of that situation is often the simplest: fix the original module, put it back where it belongs, and verify that the transmission responds the way it should. That’s exactly what we do every day at UpFix.

We repair Allison TCMs at the source of the trouble—driver stages, power regulation, aging capacitors, and the tiny solder joints that can crack under heat and vibration. Then we validate the fix under load so you’re not guessing when the bus returns to service. Because it’s your original unit, it goes back in plug-and-play and keeps your existing calibration. No reprogramming detours. No “almost right” replacement that behaves a little differently. Just a bus that shifts smoothly, pulls away from the curb, and completes its route like it should.

That reliability pays off in the places that matter. It keeps your transportation plan stable, so the first stop of the day doesn’t become the last. It keeps your kids safe by reducing roadside delays and awkward handoffs. And it keeps the roads safe around your schools by making bus traffic more predictable for everyone else. Safety isn’t a slogan here—it’s the natural result of equipment that works the way it’s supposed to.

If you’re ready to move forward, tell us about the bus, the codes you’re seeing, and what the driver is experiencing. We’ll confirm whether the TCM is the likely issue and help you start the repair. If you need a quote or bulk pricing for multiple units, we’ll provide that too, along with clear turnaround expectations so you can plan coverage. When you’re set to ship, we’ll walk you through packing and labeling by bus number or VIN, and we’ll keep you updated while the module is on our bench. If you’d like to review the warranty and what our final testing includes, we’ll send that over in plain language so nothing is left vague.

Getting a TCM repaired isn’t about checking a box—it’s about getting back to steady mornings, on-time arrivals, calmer curbs, and the kind of normal that lets everyone focus on learning. When you’re ready, we’re here to help you get there, and to help keep school districts safe, your kids safe, and our roads safe every day.

upfix.com

upfix.com 888-979-9343

888-979-9343